Small-scale oilseed processing

Practical Action

Water assisted. Here the finely ground oilseed is either boiled in water and the oil that

floats to the surface is skimmed off or ground kernels are mixed with water and

squeezed and mixed by hand to release the oil.

Ghanis. A ghani consists of a large pestle and mortar rotated either by animal power or

by a motor. Seed is fed slowly into the mortar and the pressure exerted by the pestle

breaks the cells and releases the oil.

Manual pressing. Here oilseeds, usually pre-ground, are pressed in manual presses.

Some pre-heating and the addition of water can improve yields.

Expelling. An expeller consists of a motor driven screw turning in a perforated cage. The

screw pushes the material against a small outlet, the "choke". Great pressure is exerted

on the oilseed fed through the machine to extract the oil. Expelling is a continuous

method unlike the previous two batch systems.

Solvent extraction. Oils from seeds or the cake remaining from expelling is extracted

with solvents and the oil is recovered after distilling off the solvent under vacuum. This

process is usually only carried out in large scale production plants and is not suitable for

small scale production.

Most small enterprises will find that small expellers are the best technology choice. Methods

such as water extraction and manual pressing only produce small amounts of oil; the extraction

efficiencies (the percentage recovered from a possible maximum) are low and labour

requirements high. Solvent extraction while highly efficient involves very substantial capital cost

and is only economic on a large scale. There is also a health and safety risk from using

inflammable solvents.

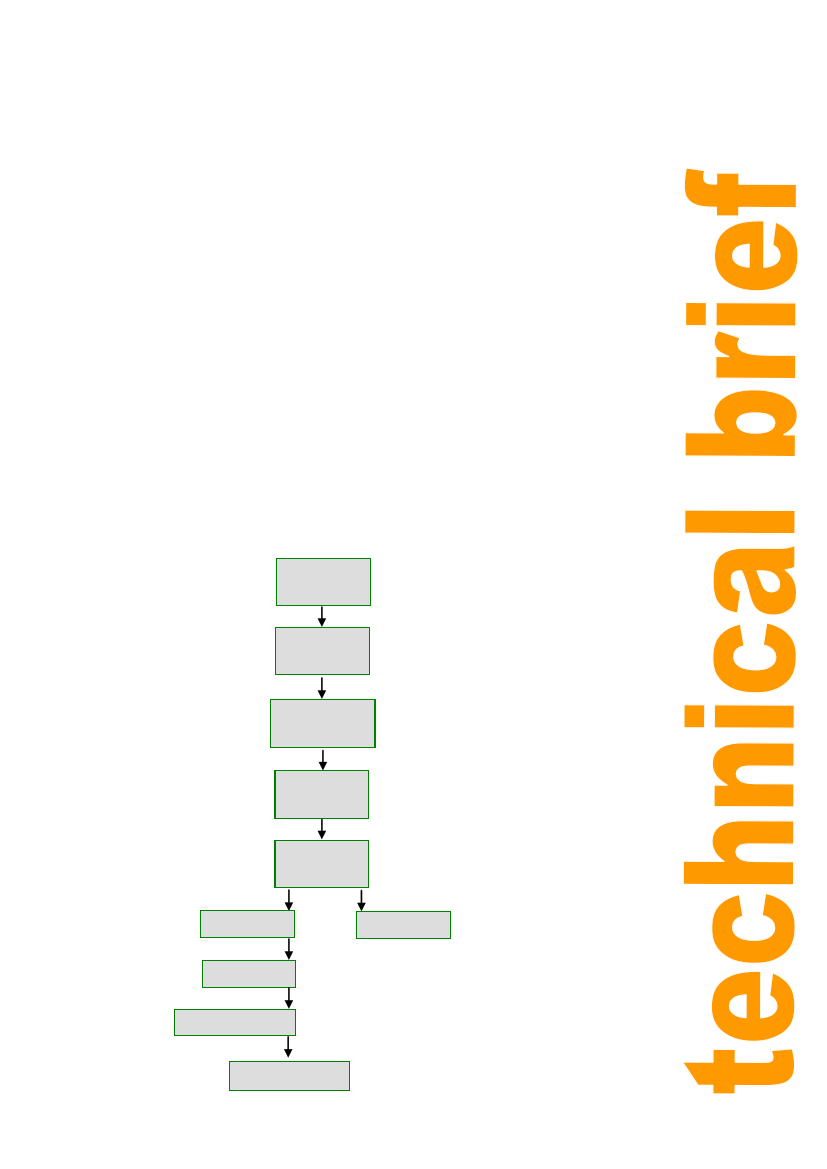

The basic steps involved in processing oilseeds by expeller are shown in the flow diagram below.

Flow diagram

Storage

Cleaning

Decortication

Shelling

Milling

Grinding

Oil

Expelling

Crude Oil

Filtering

Deodorising

Cake

Neutralising

3